Chemical Conversion Coating

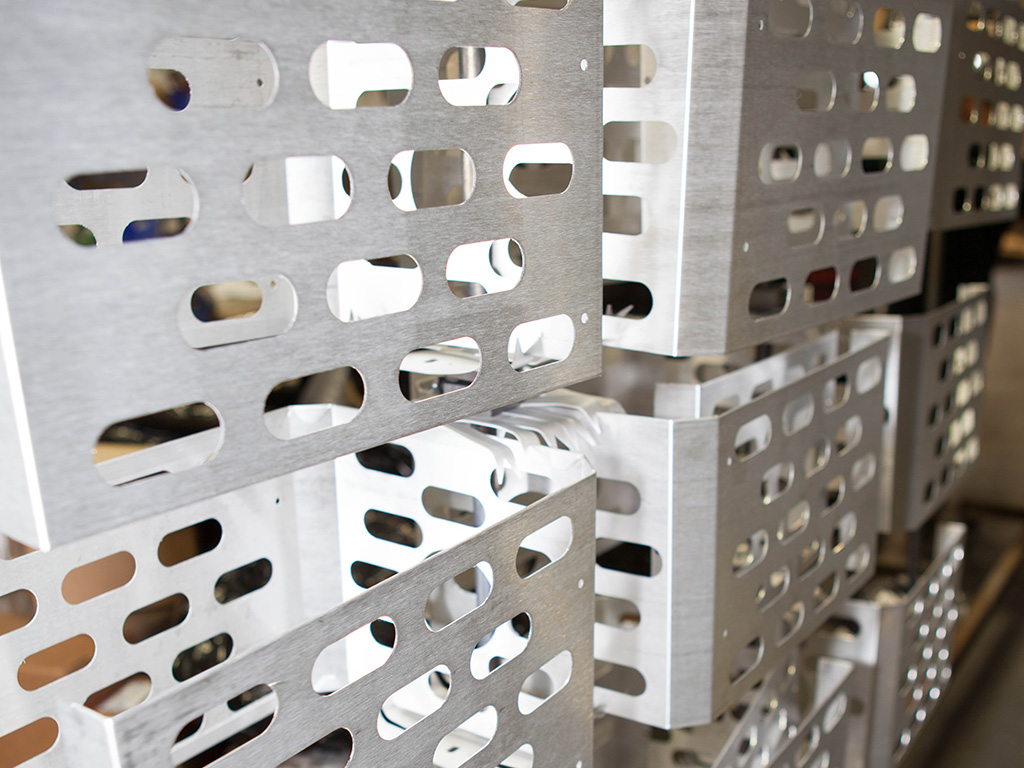

Chemical conversion coating (also known as chemical film, chromate conversion coatings, chromating, alodine and alodining) provides economical corrosion protection and a superb surface for painting and powder coating aluminum parts.

Unlike anodizing, which creates a non-conductive coating, chemical conversion coatings provide a low electrical resistance and preserve the electric conductivity of your aluminum parts. Chemical conversion coatings also do not require electricity and therefore are more economical. All parts go through a multi step surface cleaning process prior to being coated.

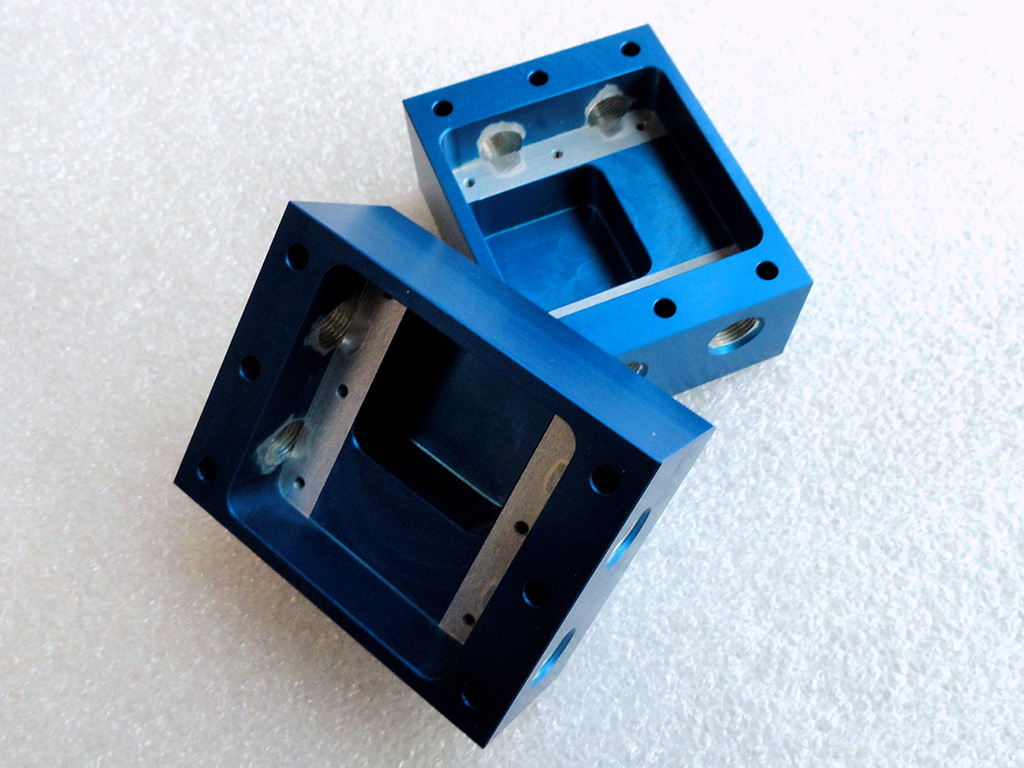

While Chromating is typically either clear or coloured, Altech only offers clear at this time.

Classifications of Chemical Conversion Coatings

Chemical conversion coatings are generally classified as follows:

Class 1A Coatings: coatings for maximum protection against corrosion and maximum paint adhesion.

Class 3 Coatings: coatings for corrosion (thinner than Class 1A) and intended for electrical applications where low electrical resistance is required relative to Class 1A coatings and anodizing.

Specifications of Chemical Conversion Coatings

Altech Anodizing Ltd.’s standard processes for chemical conversion coating are generally in accordance with the process requirements of MIL-DTL-5541F with the one difference being the exception of paragraphs 3.6.1 and 3.6.2, stating the requirement that production parts undergo a paint adhesion test and a salt spray test to determine corrosion resistance. We do not regularly perform those tests for cost reasons. However, given our strict chemical and process controls, we are confident that all parts processed by us would pass those tests. We can arrange to have both the corrosion and paint adhesion testing of test specimens or your parts after processing if requested.

RoHS Compliant Chemical Conversion Coatings

ROHS Compliance Conversion Coatings are a requirement for the vast majority of products produced for the European market these days and is the direction all responsible markets are heading.

We offer one type of Chemical Conversion Coatings to meet your specific needs. It is clear in colour and meets the RoHS guidelines as it complies with the requirements of the European Union directive for banned substances and does not contain hexavalent chromium, mercury, cadmium, lead and/or other banned substances.

Currently, despite testing and research, we do not offer a chemical conversion coating which is both RoHS compliant and gold in colour.

Lets Work Together

We are Your Partner, not just a Supplier.