What Is Anodizing?

Anodizing is a multi-step process where aluminum is electrochemically processed to form a layer of aluminum oxide (anodic) coating to protect the aluminum beneath.

This aluminum oxide is not applied to the surface like paint, but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel.

Anodizing also has a highly porous structure that allows for cosmetic processes. such as coloring and sealing, to take place during the anodizing process.

Anodizing Specifications

All of the following fall under the standard anodizing mil spec Mil-A-8625F.

SPECIFICATION

PROCESS

Type I Anodizing Not offered – Chromic Acid Anodizing Type II Class 1 (aka AMS 2471) Standard Clear (non-dyed) Anodizing

- Thickness: 0.0002” +/- 0.00005”

Type II Class 2 (aka AMS 2472) Standard Colored (dyed) Anodizing

- Color to be specified by customer

- Thickness: 0.0007” +/- 0.0002”

Type II Class 1 – Hard / Marine A thicker version of Standard Clear Anodizing

- Thickness: 0.0012” +/- 0.0002”

Type II Class 2 – Hard / Marine A thicker version of Standard Color Anodizing

- Color to be specified by customer

- Thickness: 0.0012” +/- 0.0002”

Type III Class 1 (aka AMS 2468) Engineered Hardcoat (non-dyed)

- Thickness: 0.002” +/- 0.0002”

Type III Class 2 (aka AMS 2469) Not offered - Engineered Hardcoat (dyed)

Which Alloys of Aluminum Can Be Anodized?

Theoretically, all the alloys of aluminum can be anodized. However, in practice the alloy must be properly selected to achieve the desired mechanical properties of the part while also providing an acceptable appearance.

Benefits of Aluminum Anodizing:

- Corrosion resistance

- Abrasion resistance

- Insulation from electricity

- Adhesion

- Aesthetic enhancement

- Hard like a sapphire

- Transparent

- Insulating

- Static-resistant

- Non-chipping

Aluminum Alloys Guidline

1000 Series

These “pure” aluminum alloys are relatively soft and provide a clear, bright finish for cans and architectural applications (e.g. 1100 or 1175). The 1000 series alloys are not suitable for hardcoating.

2000 Series

The 2000 series is alloyed with copper. These are very strong and hard materials, developed for the aerospace industry (e.g. 2219 or 2224). They are not suitable for decorative applications since a yellow, non-weather resistant coating is achieved. Special current control techniques are required for wear resistant (hardcoating) applications.

3000 Series

These alloys incorporate manganese into the aluminum to form sheet material (e.g. 3003 or 3004). Properties are similar to the 1000 series, but a grayish brown color is produced that is difficult to match in successive batches. They can be used for cans, lighting and as a base for painted architectural products.

4000 Series

The 4000 series should be avoided due to the high silicon content which forms a heavy black smut when anodized. The coating formed is dark gray in appearance. Some of these alloys (e.g. 4043 and 4343) have been used for dark gray architectural finishes.

5000 Series

Magnesium is the primary alloying constituent in the strong, ductile 5000 series. These are important alloys, producing clear, corrosion resistant coatings. Applications include lighting, food utensils, boats (e.g. 5052 or 5252) and architecture (e.g. 5005 or 5657).

6000 Series

These are strong, ductile alloys that provide clear coatings with good properties for structural and architectural applications (e.g. 6063 or 6463). The alloying elements are magnesium and silicon. Some of these alloys are strengthened by heat treatment and are thus suitable for hardcoating (e.g. 6061 or 6101).

7000 Series

The 7000 series is alloyed with magnesium and zinc, which imparts strength and ductility for clear, corrosion resistant automotive trim (e.g. 7029, 7046 or 7075). These alloys can also be used for hardcoating.

Surface Preparation

Surface preparation prior to anodizing is a critical step towards achieving the best anodizing results!

Please note that the only Surface Prep services provided by Altech are on parts that are flat. All other parts must be prepared and ready to be treated when they arrive.

Polishing

Manual or mechanical polishing creates a lustrous surface resulting in a very high-end and unique finish that stands out from traditional anodized and plated parts. Some clients choose not to further process their products after polishing.

Time Saving (Scotch Brite)

Through this unique Time Saving process, Altech can perform simple cosmetic alterations to your product before it’s processed. Time Saving is available in 3 types of grit finishes and can remove harsh edges, smooth out unwanted conductive points, or simply create an attractive texture to your aluminum materials.

Quality Assurance

Our strict product processing guidelines is the reason that we are trusted by many of Canada’s largest volume producers as well as the assurance that you will receive consistent and excellent service at Altech.

As part of our overall quality assurance, all parts are inspected prior to processing as well as during packaging to ensure compliance with both our and your specifications.

We also record all our chemical baths as well as anodizing parameters to ensure high-quality, repeatable results. We run our own test samples for analysis and retention to ensure chemical and anodizing parameters are perfect.

Tank Sizes

No part is too small for Altech; most are not too large, either. Our anodizing and process tanks are longer, wider, and deeper than most conventional tanks allowing us to run larger parts and/or more parts per load translating into cost savings for you.

Call us to confirm our tank sizes depending on your needs.

Masking and Plugging

Unless protected, every surface of a part will be anodized or chromated/alodined. In many instances, specifications call for contact points, clear threads, non-coated areas, or the like.

We carry a wide range of masking and plugging materials so that we can provide you with immediate and comprehensive masking services to your exact specifications.

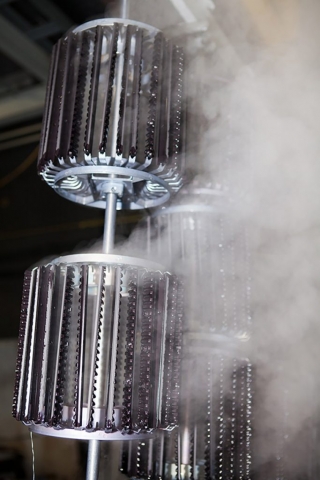

Chemical Cleaning

All parts to be anodized or chromated undergo a chemical cleaning prior to processing in order to removes impurities, machining oils, and other contaminants found on products after the manufacturing process.

The level of cleaning achieved with our method cannot be matched by over-the-counter cleaners or do-it-yourself products.

Our cleaners allow us to strip previously anodized parts so that they can be refinished.

We also offer chemical cleaning and stripping of parts for clients wishing to achieve a perfectly clean surface prior to mechanical polishing or processing.

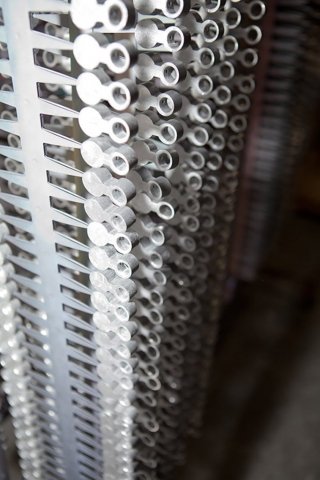

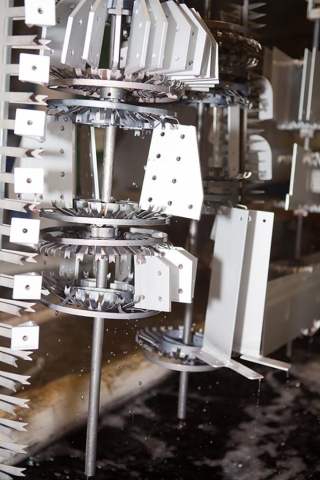

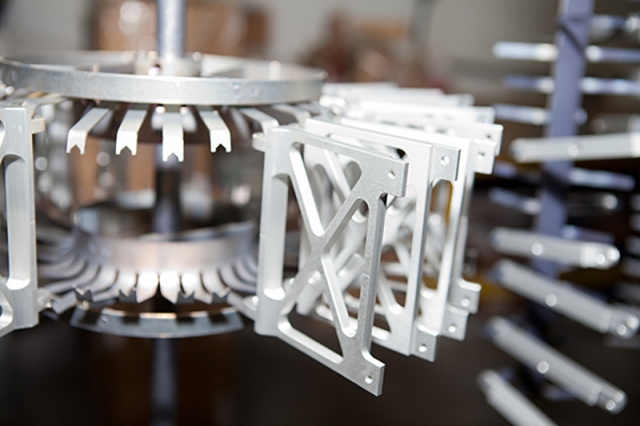

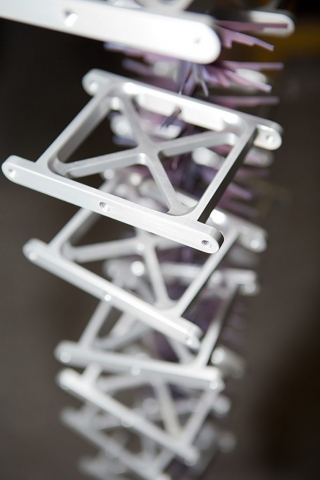

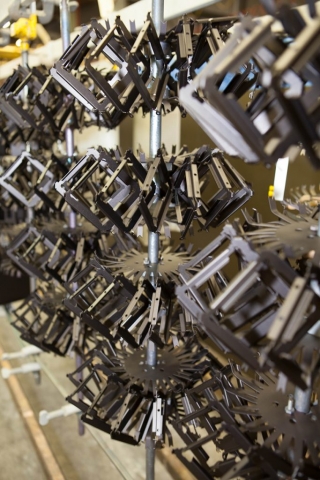

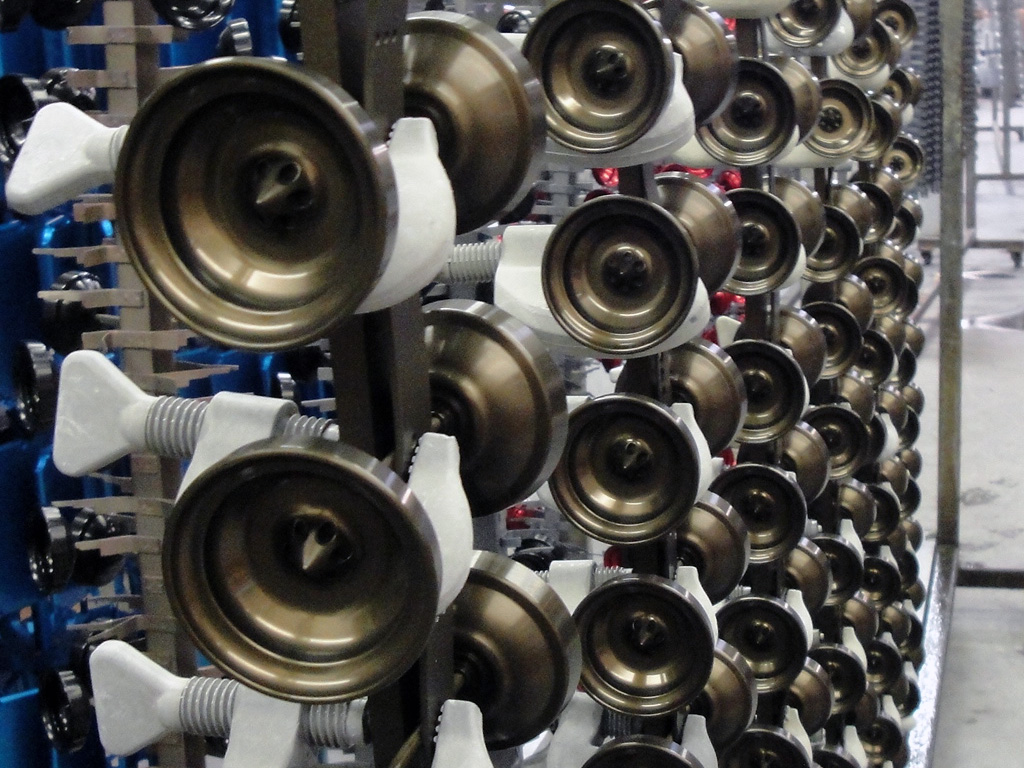

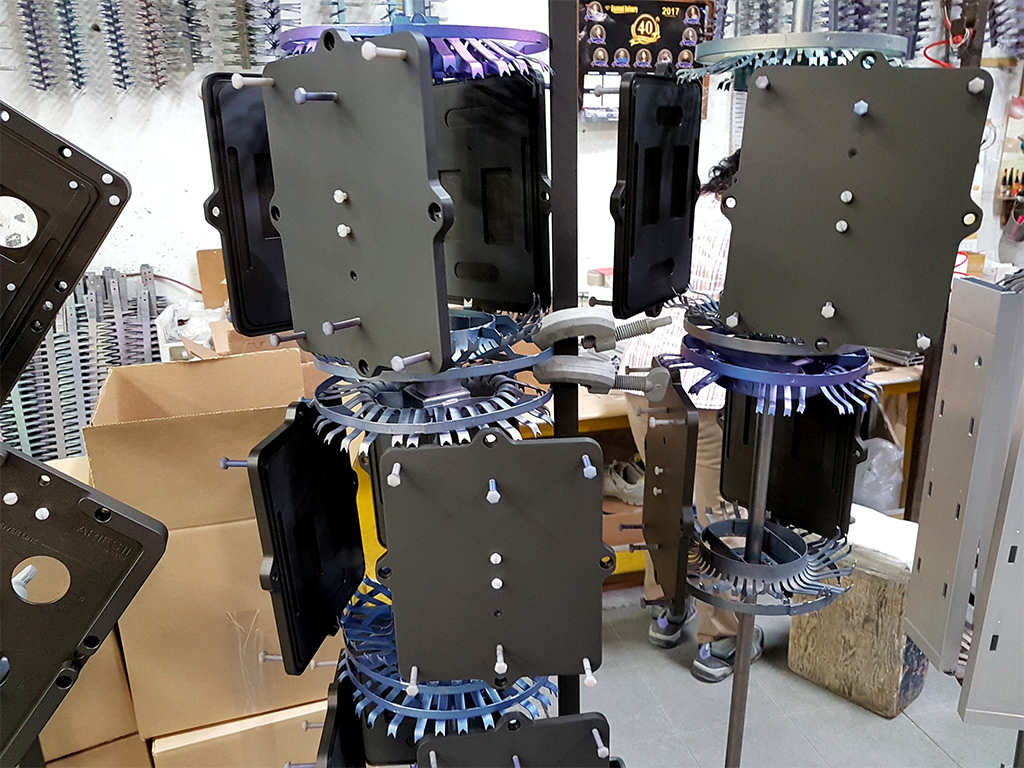

Racking & Fixturing

When aluminum parts arrive in the anodizing shop, they need to be unpacked and racked according to clear instructions.

The basic functions of racking are to hold the part tight during the transfer between the different process tanks as well as to provide sufficient contact to the part so that a consistent layer can be formed.

Altech has refined this process so that the size integrity of any whole or part dimensions of your product (small or large, simple to complex) are maintained, while the point of contact where the product is racked is minimized. We can also custom design special features to process your parts.

Bronzing Anodizing

Architectural bronze anodizing is a multi step process involving the application of current and tin based chemical solutions to essentially imbue a colour into the anodic coating. The bronze colour may range from light champagne to deep brown depending on processing time, but results in an extremely lightfast product perfectly suited for outdoor applications.

Bronzing Anodizing Tip

Only 6061, 6063, 5005, 5052 alloys may be bronzed.

Type II Anodizing

Type II Sulphuric Acid Anodizing

Type II anodizing is available in Class 1 clear (Non-Dyed) or Class 2 (Dyed).

Coating Thickness of Type II anodizing will vary from 2/10 of a thou (.0002 inches) for non-dyed, anodizing to 8/10 of a thou (.0008 inches) for colour dyed anodizing.

Anodizing Tip

Type II Sulphuric acid anodizing can be done on a vast range of aluminum alloys. The less alloying elements in the aluminum the better the result, especially when dying the anodic coating.

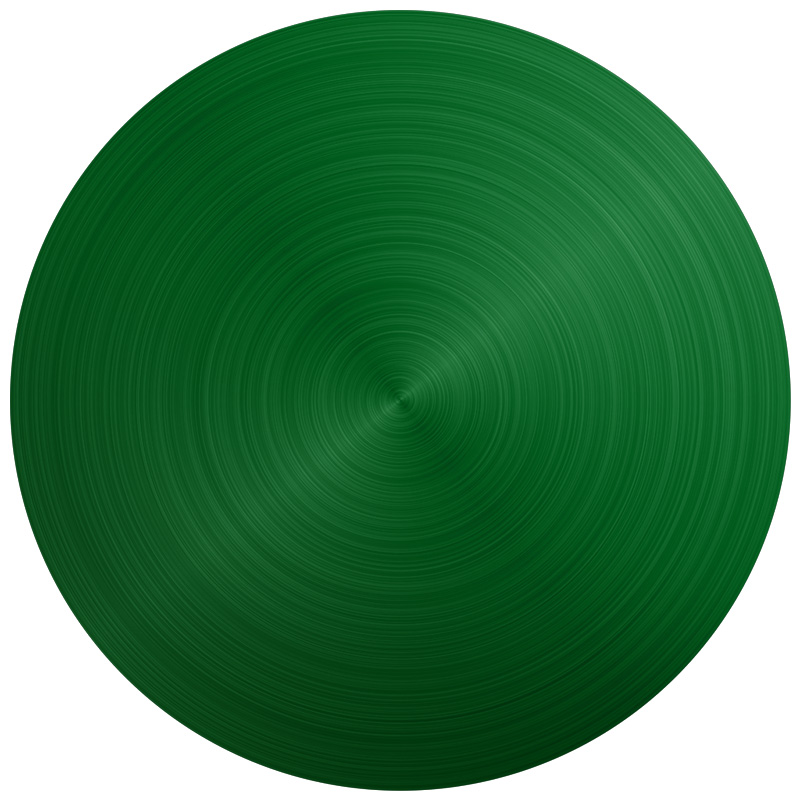

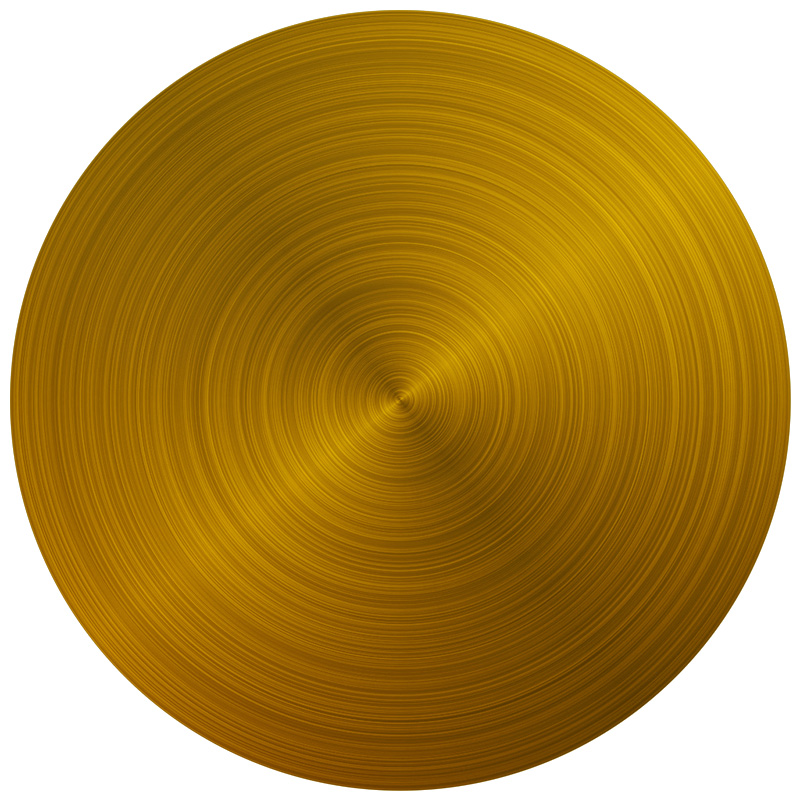

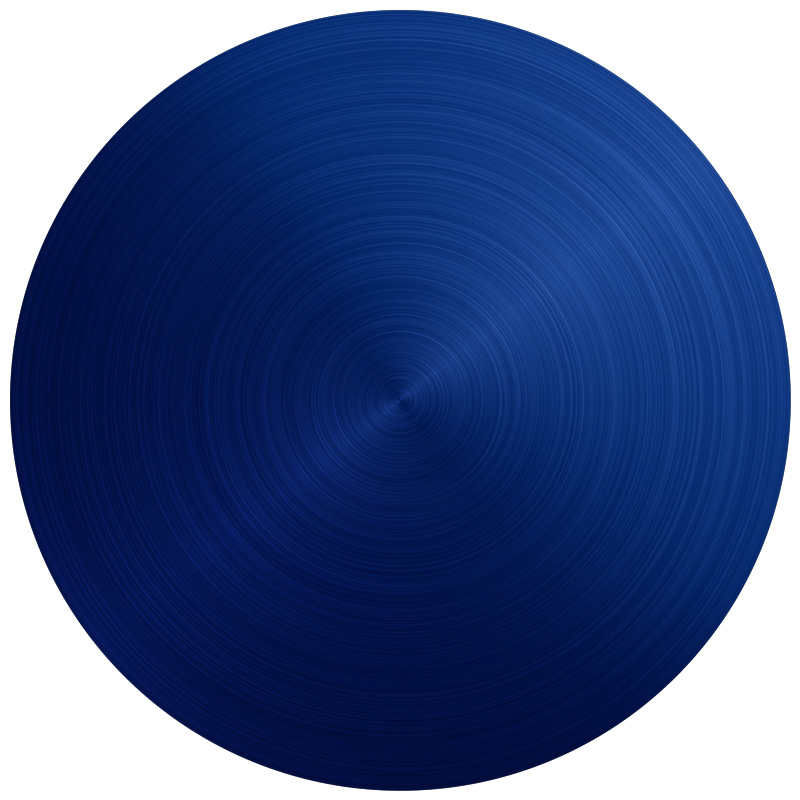

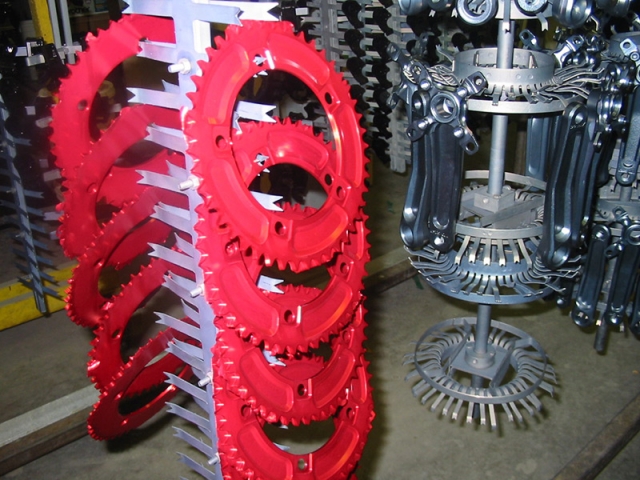

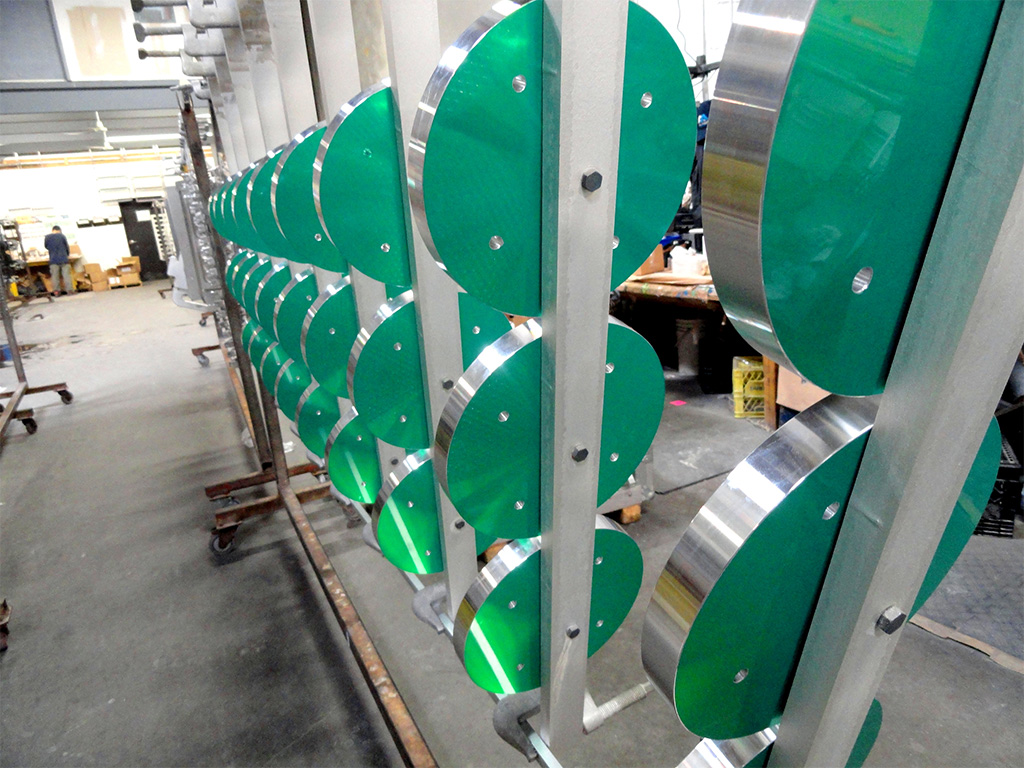

Anodizing Color Samples

Colours

Altech offers Class 2 anodizing in 9 standard colours:

- Black

- Grey/Pewter

- Red

- Orange

- Gold

- Emerald Green

- Forest Green

- Blue

- Purple

Custom colours also available.

Typical Type II Anodizing Applications

- Sporting goods

- Marine products

- Electrical products and enclosures

- Aerospace

- Automotive

- Motorcycle

- Appliances

- Architectural aluminum-door frames, windows frames and extrusions

- Lighting fixtures

Allow Series Colour Overtones

See the following chart for an approximate guide line to what type of natural colour change each alloy typically undergoes during Type III anodizing:

Alloy Series

Color Overtones

1000 Grey/Green 2000 Bronze (not recommended) 3000 Grey 4000 Grey 5000 Grey/Brown 6000 Dark Grey/Green 7000 Bronze Castings Grey (not recommended)

Type III Anodizing

Type III Engineered Hardcoat

Type III anodizing is done under tightly controlled conditions where the temperature of the sulphuric anodizing solution is held near 32 F – or 0 C – with a very high electrical current applied to the product. The result is a durable and hard anodic coating typically in the range of 60-70 on Rockwell C-Scale.

Type III anodizing results in a natural colour change to the aluminum and will vary from light tan to black. It is dependent on a number of factors including the temperature, current, duration of anodizing, alloy, and thickness.

Type III Anodizing Tip

Do not be fooled by anodizers who claim they can produce Type III-like anodizing in their Type II tanks. Yes, the coating thickness will be similar but the properties of the coating will not. Type III anodizing takes special equipment and know-how. When you specify Type III engineered hardcoat to Altech we provide it to you using our dedicated Type III tank.

Best results with Type III are achieved with 5000, 6000 and 7000 series alloys. High copper alloys like the 2000 series are not desirable. Neither are castings.

Lets Work Together

We are Your Partner, not just a Supplier.